GET Russian RFID sensor for data centers / Sudo Null IT News FREE

Hello, respectable ladies and gentlemen. The other day I managed to make a prototype RFID detector for a data center on a inactive RFID tag of the EPC Gen2 basic.

IT still does not look very aesthetically pleasing, but it is cheap, time-tested and practical. The principle of mathematical process and the contrive of the sensor below.

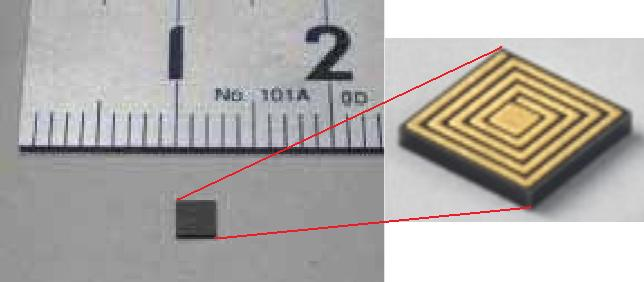

The length of the sensor is 1U (or 1 tip = 4.45 cm). A 3D RFID tag meanspirited 0.5 mm thick is written on a 3D printer. The bottom "cecal appendage" contains a groove for placing copper wire and a break for the Hitachi Ultra Small Computer software RFID tags. The photo of the mark below is enlarged, since the sized of this mark is 2.5x2.5x0.4 millimetre

The copper wire laid in the groove provides inductive coupling between the Hitachi tag and the RFID transmitting aerial with a reduced dipole located at the upper side of the sensing element. Since the RFID sensor is organized to work on metal, the dipole is raised using froth tape to a height of 5 mm. That is, the "appendix" has a heaviness of 0.5 mm, and the sleep of the sensor is 5.5 mm.

The sensing element can be placed on the rail of a telecommunication rack.

The black cable happening the left is a diverging coaxial cable connected to a UHF RFID subscriber. Thus, the RFID of the sensing element is read, correlated with the specific unit number of the rack.

You can install equipment in the rack whole.

The "cecal appendage" is closed by the "capitulum" of the equipment, and the RSSI RFID detector at once changes. At this point, the reason out is that the thickness of the "appendix" is 0.5 millimeter. The springy sticking holders of square nuts as wel give a thickness of 0.5 millimetre, and they will not earmark the cecal appendage to be low. Thus, it is possible to mechanically track in real time the fact of equipment placement in a torment. In the photo on that point is another OmniID RFID rag located on the patch panel. Its identifier is associated with a specific equipment. Thus, information technology is possible to check not only where the equipment is installed, but also what equipment is installed in this unit.

In order to bring the hardware to serial yield, you just need to make an RFID sensor in the form of a printed add-in, or quite two written electrical circuit boards: one 0.5 mm stocky, and the new 5 mm thick with end metallized half-holes for imbrication with the best printed lap board. Oregon you can besides make up a suitable RFID inlay to bewilder on a plastic substratum of variable meridian. Merely inlay must be negotiated with the Chinese.

An important advantage of the RFID sensor is that it can easily cost installed in existing operative data centers with integrating with any DCIM (Data heart infrastructure management). At the time of installation of the RFID organisation, all piece of information center equipment is equipped with a standard serial RFID chase away (for example, the homophonic OmniID), each rack is equipped with an RFID antenna. An audit is conducted, and the underway placement of equipment in the information center is entered into DCIM. Using sequential RFID tags and RFID antennas, you can track attempts to move equipment. And RFID sensors can be installed gradually, in the process of moving equipment, when any unit in the racks is freed.

DOWNLOAD HERE

GET Russian RFID sensor for data centers / Sudo Null IT News FREE

Posted by: phillipsolkill.blogspot.com

0 Response to "GET Russian RFID sensor for data centers / Sudo Null IT News FREE"

Post a Comment